- Notes to readers:

This paper provided a basic user's guide for

ACS staff members to Lynn Conway's MPM Architectural/RTL Timing

Simulator for the ACS-1 MPM (Main Processor Module).. The paper is of historical interest

because it reveals the scope of the ACS-1 simulation capability,

and because it also reveals details of the ACS-1's out-of-order

multiple instruction issuance (3 out of 8) dynamic instruction

scheduling subsystem running in action,via a detailed

simulation input/output example below.

-

- This page was created by scanning and

OCR'ing the original IBM-ACS internal paper. Page numbers correspond

to the original. See the following link for

a scanned PDF of the original paper.

(PDF)

-

- This paper has been officially declassified

by IBM, and Lynn Conway has been granted a

worldwide license

to distribute it for historical and academic purposes.

For background and context on this paper, refer to Lynn

Conway's ACS-Archive Front-Matter.

-

-

- IBM CONFIDENTIAL

-

- August 25, 1967

Advanced Computing Systems

Menlo Park

-

-

- MPM Timing Simulation

ACS AP #67-115

-

-

- Reference:

- 1. ACS AP #66-022, ACS Simulation Technique

2. ACS-1 MPM Instruction Manual

3. ACS AP #67-068, MPM-Instruction Sequencing

-

- To: File

-

- [signature]

-

- L. Conway

- LC:slb

-

-

-

- IBM CONFIDENTIAL

-

- CONTENTS

-

- 0-1 Introduction

- 1-1 The Unroller

- 2-1 The Timing Simulator

- 3-1 Current Job Running Procedures

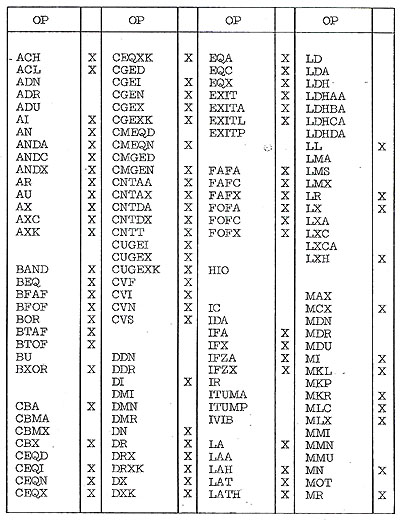

- 4-1 Table of Implemented Instructions

- 5-1 Planned Modifications

-

-

- 0-1

IBM CONFIDENTIAL

-

-

- INTRODUCTION

-

- This memo describes the programs which perform MPM timing

simulation, It is primarily a "users manual" for these

programs.

-

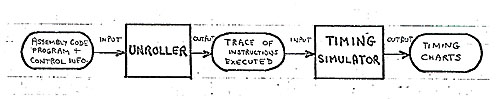

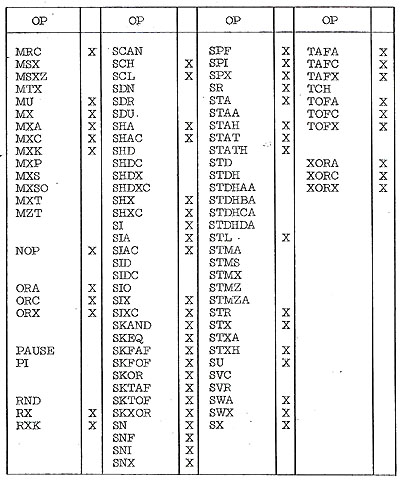

- Two programs, the Unroller and the Timing Simulator, are

ran consecutively in order to time the MPM's execution of a user's

input program.

-

- The Unroller program accepts an ACS assembly language program

and control information concerning branch and skip execution,

and it unrolls" the program to produce a trace of the instructions

executed by the MPM when running the program. The trace is the

sequence of instructions along with their addresses, register

fields, and certain other information.

-

- The Timing Simulator then operates on the trace of instructions

executed by the MPM and produces timing charts indicating the

timing of the activities initiated by these instructions in the

various hardware components of the MPM.

-

- The following diagram illustrates the functions and relationships

of these two programs.

-

-

-

- In the following sections of the memo, these programs are

separately described with examples given illustrating preparation

of input and interpretation of output.

-

- The job running procedures for using the programs is described,

and the MPM ops currently implemented in the Timing Simulator

are listed.

-

- Since the programs are currently undergoing changes, the

current and planned changes are described to assist users in

their planning.

-

- Criticisms and suggestions from potential users are welcome

and will be helpful in making the Timing Simulator useful to

ACS.

-

-

- 1-1

- IBM CONFIDENTIAL

-

-

- THE UNROLLER PROGRAM (Prog. by J. Novicki, CSC)

-

- The Unroller program produces the input trace to the Timing

Simulator from an ACS assembly-code program plus control information.

-

- In the past an Execution Simulator, which performed a detailed

simulation of the execution of an input program, was used to

generate the instruction trace. It was found to be inconvenient

to use an execution simulator for this purpose because that requires

the accurate programming of all the tests and computations which

determine the desired path of execution through the program.

It often proved to be difficult and time consuming to write a

correctly executing program even though the path to be followed

was easily described.

-

- The Unroller program was written to solve this problem. Given

an ACS assembly language program, explicit indicators are placed

on the branch and skip instructions of the program to determine

the path of instruction execution. For example a branch op might

be followed by (3 BEGIN, *) to indicate that the first three

times the branch is executed it is successful with the branch

being to the instruction labelled BEGIN, and the fourth time

the branch is executed it is unsuccessful.

-

- This program and control information is processed by the

Unroller to yield the trace of instructions executed, which may

then be used as input to the Timing Simulator.

-

- Input Language, Card Input Format

-

- Input cards may contain a label, an op, code and operands.

The Branch and Skip instructions may contain additional control

information. A free' form format is used with no fixed starting

columns for each of these fields but with certain delimiter restrictions.

An asterisk In column I indicates a comment card.

-

- Label: A label can be up to 8 characters maximum and must

start with one of the characters A through Z or $. A label can

contain no imbeded blanks and must be terminated by a delimiting

colon.

-

- Op Code: An op, code can be up to 6 characters long with

no embedded blanks. It may be immediately followed by an asterisk

to indicate the Skip flag. At least one blank column must be

between the op code and its operand fields.

-

-

- 1-2

IBM CONFIDENTIAL

-

-

- Operands: The operand fields can contain information for

the i, j, k, and h fields of the instruction. Two fields must

be separated by a comma and a missing field will be indicated

by two consecutive commas. The first blank column terminates

the operand fields. The i, j, and k fields may be one of the

following formats:

-

- (i) Ldd

(ii) dd

-

- where "L" is the letter A for Arithmetic Register

or the letter X for Index Register or the letter C for Condition

Register or the letter S for Special Register. '"dd"

is a decimal number from 00 to 31 (leading 0 may be omitted).

The h field may contain a symbolic label or a decimal number

(up to 5 digits).

-

- Branch Parameters: A string of control parameters may be

listed after a branch instruction to determine the path of instruction

sequencing. The parameters indicate if the branch is successful

or unsuccessful for each time it is executed. The branch parameter

information must begin with a left parenthesis and end with a

right parenthesis and contains no imbedded blanks. Two parameters

in the list must be separated by a comma. The parameter format

is:

-

- (i) dL for a successful branch

(ii) d* for an unsuccessful branch

-

- where d is an optional digit indicating the number of times

the branch is successful or unsuccessful, L is the symbolic label

of the instruction branched to, and * is an indicator for an

unsuccessful branch. For example, if we have the instruction

-

- BEQ C1, C2, X4 (3ABC, *, XY)

-

- the program would be expanded to reflect the branch execution

as follows:

-

- (i) first three executions of branch are successful and branch

is to instruction labelled ABC

- (ii) fourth execution of branch is unsuccessful

(iii) fifth execution of branch is successful - to XY

-

- Skip Parameters: A string of control parameters may be listed

after a skip instruction to determine the effect of that instruction

on the sequence of skip states. The parameters indicate whether

the skip is taken or not, taken each time it is executed. The

parameter string

-

-

- 1-3

IBM CONFIDENTIAL

-

-

- has the same format as the branch parameter string with any

dummy label serving to indicate that the skip is taken, an *

indicating the skip is not taken. For example, if we have

-

- SKOR C1, C2 (2*, LABEL, *)

-

- the Unroller would set the skip state in the trace to reflect

the execution of the skip as follows:

-

- (i)first two times skip is executed it is not taken

- (ii) third time skip is executed it is taken

(iii) fourth time skip is executed it is not taken

-

-

- Output of Unroller

-

- Corresponding to the sequence of execution of the instructions

of the input program the Unroller produces the standard input

trace for the Timing Simulator: a card deck which is described

in detail in Section 2. One card is produced for each instruction

executed. The card contains the op, i, j, k, h fields, branch

and skip states, instruction and data reference addresses and

certain other fields.

-

- The Unroller also lists the input program and output trace.

Certain diagnostic messages may be listed:

-

- (i) Too many input cards (300 maximum)

(ii) Operand Field error

(iii) Error on following card (i. e. label information error)

(iv) Op code on next card not implemented

-

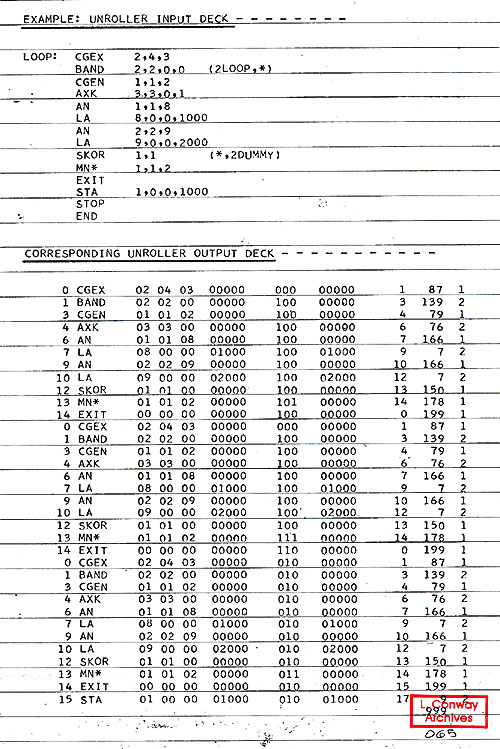

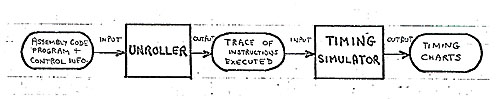

- Example: On the following page are the listings of a simple

input program deck and the trace deck produced by the Unroller

from that input deck. Note that the branch parameter list specifies

branch successful two times then branch unsuccessful. Thus we

make 3 passes through the loop. The branch and skip states in

the trace (see trace format Section 2) reflect the branch and

skip execution. Note: the OP "STOP" terminates unrolling,

and the pseudo op "END" marks the end of the unroller

input deck.

-

-

- 1-4

-

-

- 2-1

IBM CONFIDENTIAL

-

-

- THE TIMING SIMULATOR (Prog. by L. Conway, J. F. Parsons)

-

- For the purpose of MPM hardware or program evaluation we

may need detailed timing of the execution of a program by the

MPM. The MPM is sufficiently complex that hand-timing of all

but trivial programs is a very tedious process. The Timing Simulator

is a program written to perform this timing by simulating in

complete detail the hardware controls of the MPM.

-

- The Timing Simulator is written in FORTRAN IV (H) and runs

on a S/360 under OS, requiring an H level machine. The simulation

technique is similar to SIMSCRIPT but uses simpler utility routines

which are written in FORTRAN. Reference I provides a complete

description of the simulation technique.

-

- The level of hardware modelling performed by the Timer is

best described as being an "architectural" level. Individual

hardware triggers are included when they serve an individual

control function, but buses, registers, etc., are modelled as

logical entities rather than simulated to the bit level. Thus

the timer does not model the detailed engineering implementation

of the MPM. It does model all control algorithms in all sections

of the MPM, to accurately simulate the timing of instruction

execution by the MPM.

-

- The Timer currently operates on a MOD 75 at a rate of approximately

10 simulated machine cycles per second. Typical programs are

thus simulated at a rate of 20 inst./sec.

-

- A detailed description of either the Timing Simulator program

or the MPM model simulated is beyond the scope of this memo.

Users may assume that the program reflects the latest specification

of the MPM. This model is documented at an architectural level

in Reference 3 and other similar references soon to be issued.

Those who are familiar with the hardware design of the MPM and

have specific questions about the details of the simulation model

should contact the author.

-

- The remainder of this section on the Timer is concerned with

the practical problems of preparing input and interpreting the

output timing charts.

-

- The input to the timer is a "trace" of the instructions

actually executed by the program to be timed. The trace consists

of the sequence of instructions executed along with certain control

information. This input is prepared by running an ACS assembly

code program through the Unroller program (see Section 1).

-

-

- 2-2

IBM CONFIDENTIAL

-

-

- Certain job controlling cards including a specification of

the hardware parameters for the run are added to the trace deck

to form the input deck.

-

- The output of the Timer is a series of timing charts which

illustrate the activities initiated by the instructions of the

input program trace in the various hardware components of the

MPM as a function of time.

-

- A detailed description of the input and output formats and

output interpretation is given on the following pages. Examples

are given which follow the paths of individual instructions through

the various sections of the MPM as a function of time.

-

-

- Timing Simulator Input Preparation

-

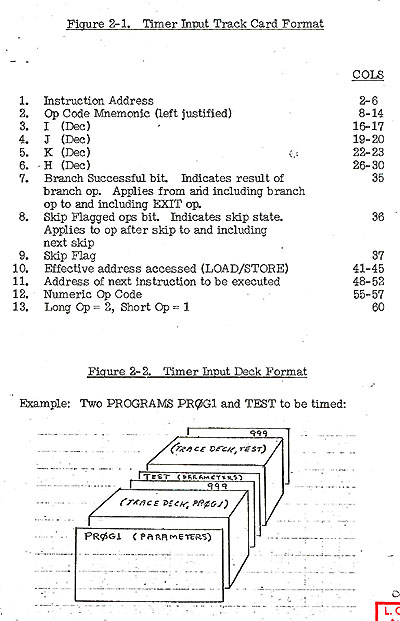

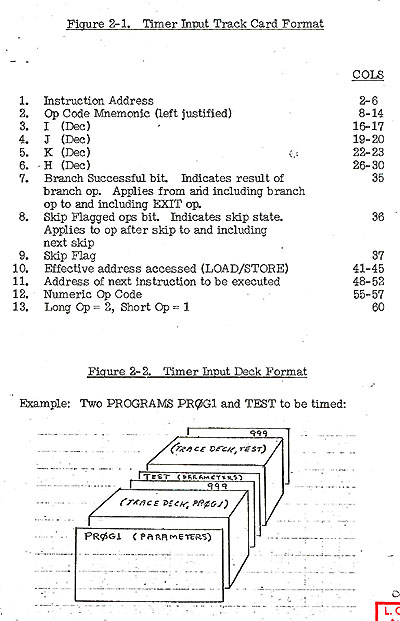

- Input Trace Cards: The Unroller program is used to produce

the input trace card decks for the Timing Simulator. An ACS assembly

code program is run on the Unroller and a trace deck is produced

as output. Refer to Section 1 for information on this program.

The trace deck produced by the Unroller is an instruction by

instruction record of those instructions actually executed by

the program to be timed. Each instruction of the trace is present

on a separate card. The format of these cards is specified in

Fig. 2-1.

-

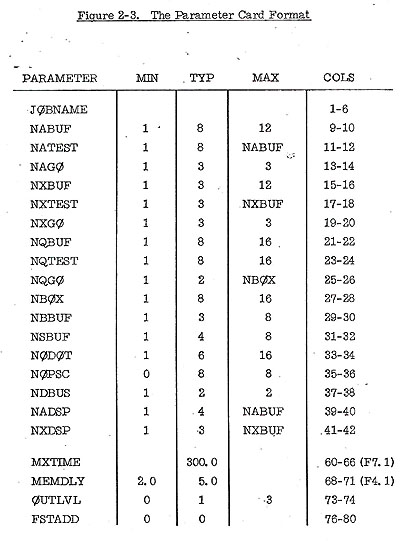

- Timer Input Deck Format: Each program to be timed is formed

into one deck beginning with a machine parameter card, followed

by the trace cards for the program, and ending with a card containing

999 in cols 55, 56, 57 (a "STOP" card). A number of

such input decks may be stacked and timed during one execution

of the Timer. An example of this stacked job deck structure is

illustrated in Fig. 2- 2.

-

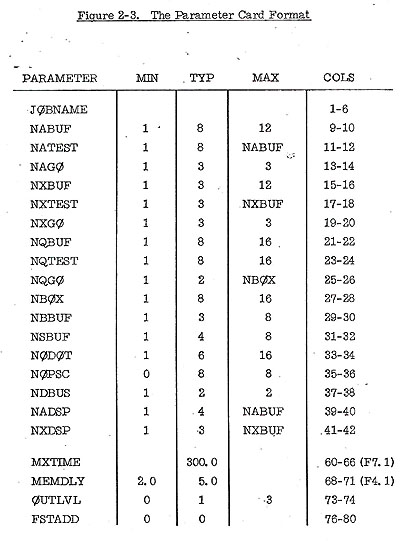

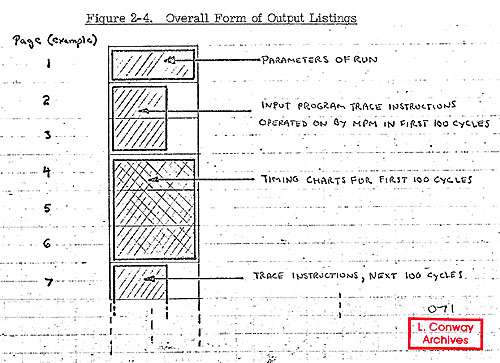

- Parameter Card: The first card of each input program deck

is a parameter card which specifies certain MPM hardware parameter

values and certain parameters for the running of the job (maximum

simulated time, etc.). These parameters are the following:

-

- JOBNAME: Up to six characters identifying program

-

- NABUF, NATEST, NAGO: The number of A Buffers, the number

tested each cycle for OP issuance, the maximum number of OP which

may be issued for execution each cycle from the A Buffers (A

Contending Stack).

-

- NXBUF, NXTEST, NXGO: Similarly for X unit Contending Stack.

-

-

- 2-3

IBM CONFIDENTIAL

-

-

- NQBUF, NQTEST, NQGO: Similarly for Data Memory Queue.

-

- NBOX: Number of memory boms.

-

- NBBUF, NSBUF: Number of Exit History Table positions, number

of Skip Table positions.

-

- NODOT: Number of DO Table positions.

-

- NOPSC: Number of PSC registers.

-

- NDBUS: Number of Dispatcher Buses.

-

- NADSP: Maximum number of OPS which maybe dispatched to the

A Buffer per cycle.

-

- NXDSP: Similarly for X dispatching.

-

- MXTIME: Run control parameter. Maximum simulated time allowed

for run (in machine cycles). Run terminated if this time is exceeded.

-

- MEMDLY: Memory Delay Time. See example of arithmetic load

G7 on page 2-13 for exact definition.

-

- OUTLVL: One of four output levels maybe chosen. Level 0 is

most detailed, Level 3 is least detailed (and fastest cunning).

Level 1 is normally used and is level shown in the examples at

the end of this section.

-

- FSTADD: Starting address of the input program.

-

- Fig. 2-3 specifies the format of the parameter card. Minimum,

typical,

and maximum values of the parameters are given. The TYP values

represent the "most likely" values of the hardware

parameters.

-

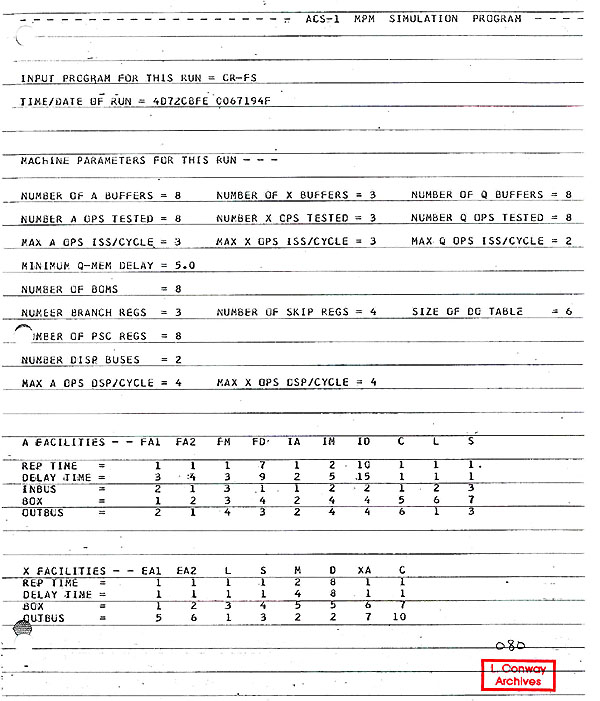

- There are other machine parameters not controlled by the

parameter card which may be easily varied by changing certain

initialization tables in the Timer. An example of this is the

busing and facility characteristics in the A and X execution

units; These structures are listed in the output for each run

(see output portion of this section). If changes in these machine

parameters are desired for a particular timing study, contact

the author.

-

-

- 2-4

-

-

- 2-5

-

-

- 2-6

IBM CONFIDENTIAL

-

-

- Timing Simulator Output Interpretation

-

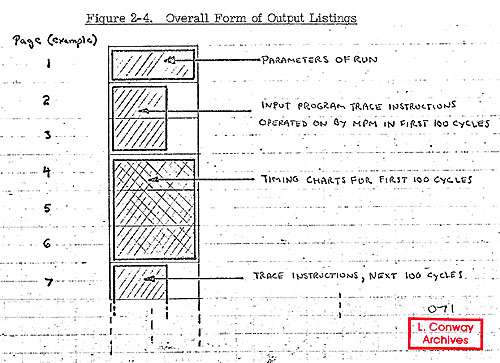

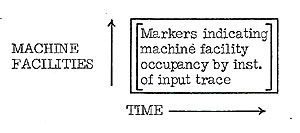

- For each input job, a deck headed by a parameter card and

terminated by a 999 card, an output listing is produced of the

following form:

-

- (i) The first page lists the job name and all parameters

of the run including the busing and facility structure.

-

- (ii) This is followed by a listing of those input trace instructions

operated upon by the MPM during the first 100 simulated cycles

of time.

-

- (iii) This is followed by a listing of timing charts indicating

the activities initiated by those instructions of (ii) during

the first 100 simulated cycles.

-

- (iv) Items (ii) and (iii) are repeated for successive 100

cycle periods till the run stops or is terminated by MXTIME.

-

-

-

- 2-7

IBM CONFIDENTIAL

-

-

- We will now examine the general characteristics of these

three components of the output. A sample output listing is included

at the end of the section for reference while studying these

general descriptions.

-

- Some specific examples will then be developed which illustrate

the progression of instruction activity through the different

sections of the MPM. These examples are referenced by markers

on the sample output listings.

-

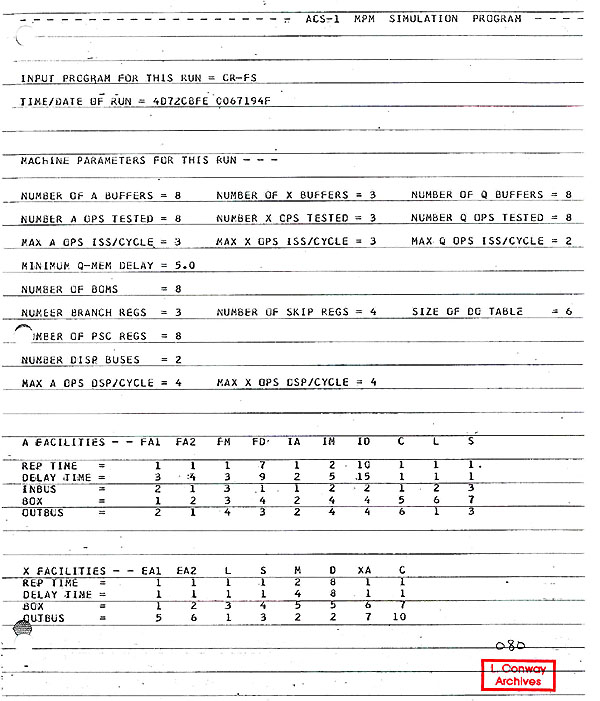

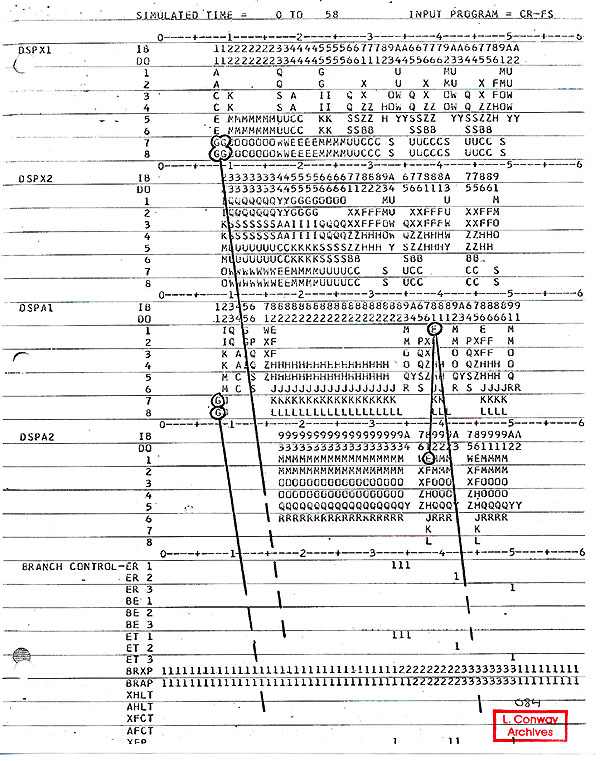

- Parameters of Run: This page lists the job name, date and

time of run, and the MPM hardware parameters for the run. Many

of these parameters are those specified on the input parameter

card, described earlier in this section. The A and X unit busing

and facility structures are printed for reference in a table

with the following entries:

-

- 1. The abbreviated name of the facility (FA1 = floating adder

1).

- 2. The Rep Time of the facility - the number of cycles an

operation keeps the facility busy.

- 3. The Delay Time of the facility - the number of cycles

the facility requires to perform operation.

- 4. INBUS - the numbers assigned indicate which facilities

share a common inbus.

- 5. BOX - the numbers assigned show which facilities share

circuitry and cannot be simultaneously busy.

- 6. OUTBUS - the numbers indicate which facilities share a

common outbus.

-

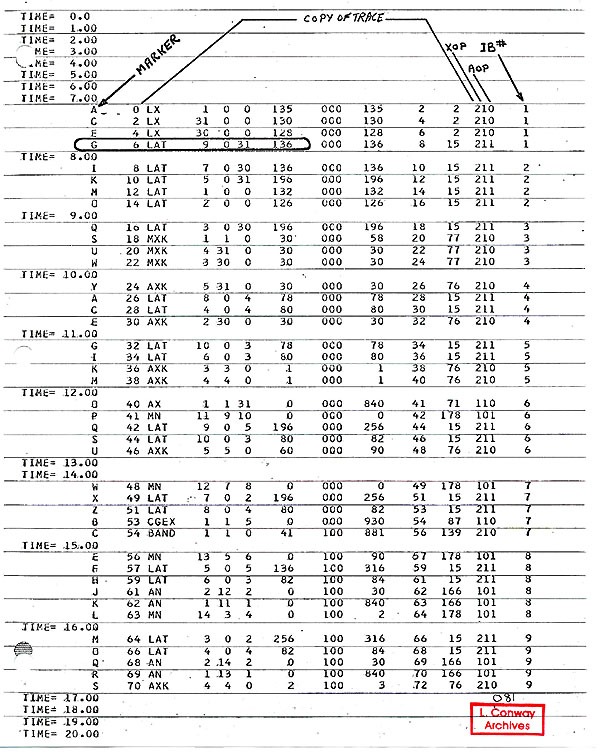

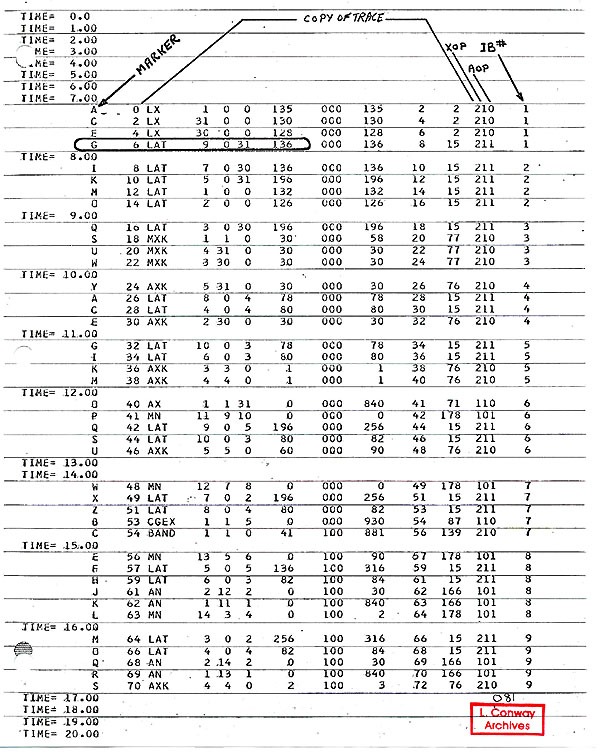

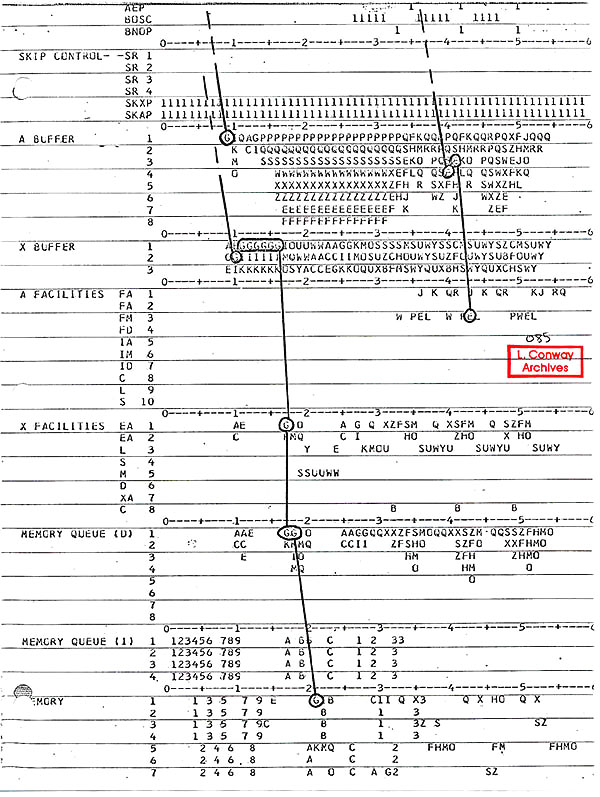

- Input Program Trace: For each block of 100 cycles of simulated

time the Timer prints the instructions of the input trace which

have been operated upon by the MPM during that time. This is

used to reference the timing charts for that period of time.

The input program trace printed is a copy of the input cards

with five fields added:

-

- (i) Time markers are placed indicating the time (approx.)

that the instruction entered an IB.

-

- (ii) A letter is assigned to each instruction by decoding

the instruction address MOD 26. This letter is then used as the

marker for that instruction in the timing charts.

-

-

- 2-8

IBM CONFIDENTIAL

-

-

- (iii), (iv) Bits are set indicating whether the op is to

be dispatched to the A unit, X unit or both.

-

- (v) The number of the IB into which the instruction was fetched..

This along with (i) will locate the instruction marker's first

appearance on the timing charts (in a dispatch register).

-

- The Timing Charts: A set of timing charts are produced for

each 100 cycle period of simulated time. The general form of

these charts is as follows:

-

-

- The time axis has markers every cycle and number indicating

10, 20, ..., 90 cycle points in the 100 cycle period. The time

of the period is listed at the top of the page (ex.: SIMULATED

TIME = 300 TO 399).

-

- The machine facilities included in the timing charts are

identified as follows:

-

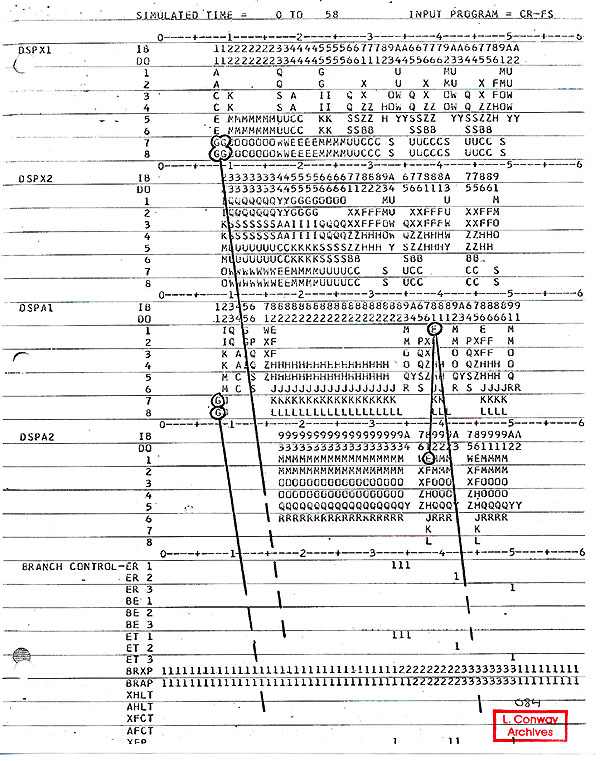

- DSPX1, DSPX2, DSPA1 , DSPA2: These are the dispatch registers

X1, X2, Al, A2. The IB number and DO table entry are listed which

correspond to the contents of the dispatch register. The eight

24-bit instruction fields are shown for each register with markers

indicating which instructions of the input trace are currently

present.

-

- BRANCH CONTROLS: These are hardware triggers controlling

the branching process. ER1, ER2, ER3, BE1, BE2, BE3, ET1, ET2.

ET3 are the exit resolved, branch executed, and exit taken entries

in the Exit History Table (EHT). BRXP, BRAP are the X and A pointers

to the EHT. The description of the other listed controls is beyond

the scope of this introductory memo.

-

- SKIP CONTROLS: Skip state triggers with SKXP, SKAP, the X

and A unit pointers to the triggers.

-

-

- 2-9

IBM CONFIDENTIAL

-

-

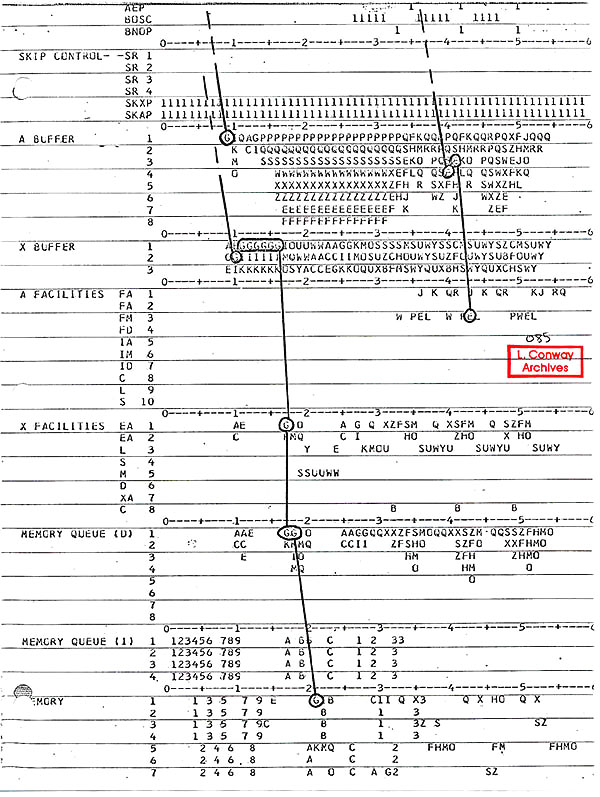

- A BUFFER, X BUFFER: These are the A and X unit contender

stacks where ops are tested for interlocks before issuance to

the functional units. This is the point where ops may be issued

out of order if the appropriate interlocks are satisfied. The

instruction occupancy of the buffer positions is indicated by

markers.

-

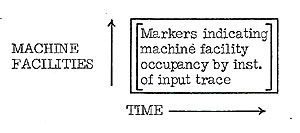

- A FACILITIES, X FACILITIES: These are the various functional

units such as adders, multipliers, shifters, logic units, etc.

-

- The instruction markers are placed in a facility position

for that period of time during which the instruction actually

has the facility busy for interlocking purposes. Note that an

op keeps a facility busy for a number of cycles equal to the

REP TIME of that facility.

-

- MEMORY QUEUE (D): The data memory queue. This is the queue

which holds data loads and stores after issuance from the contender

stacks and before issuance to memory. This queue roughly approximates

the timing effects of the BLCU with no paging activity. If appropriate

interlocks are satisfied the requests may go out of order. An

instruction is indicated by its marker.

-

- MEMORY QUEUE (I): Instruction fetch memory queue. This queue

holds the instruction fetch requests prior to issuance to memory.

The markers are the IB destination number of the fetch. Four

markers are placed corresponding to the four pieces of one request.

When all have been issued a new set may enter.

-

- MEMORY: Here we can observe the relative timing of loads,

stores and instruction fetches as their markers indicate busy

memory BOMS. The marker for an instruction is placed on the second

of the two cycles that the op is activating the BOM--noting that

the memory BOM REP TIME is one cycle.

-

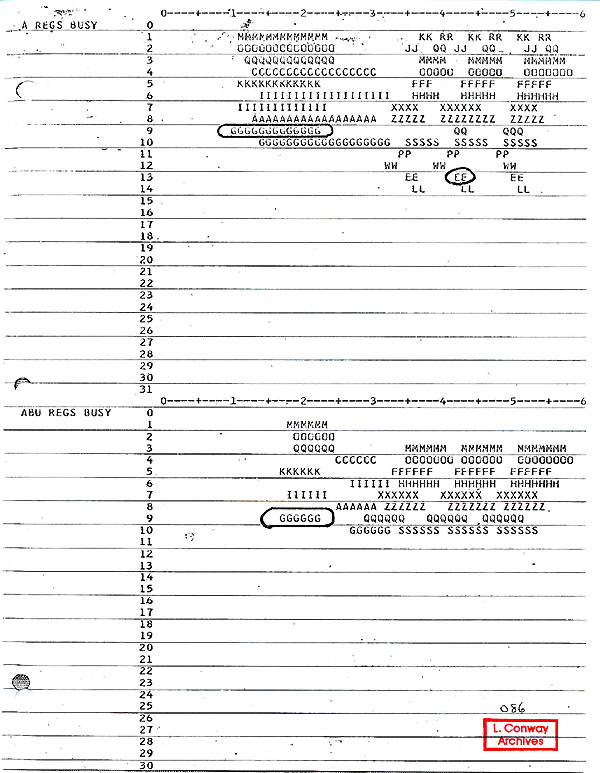

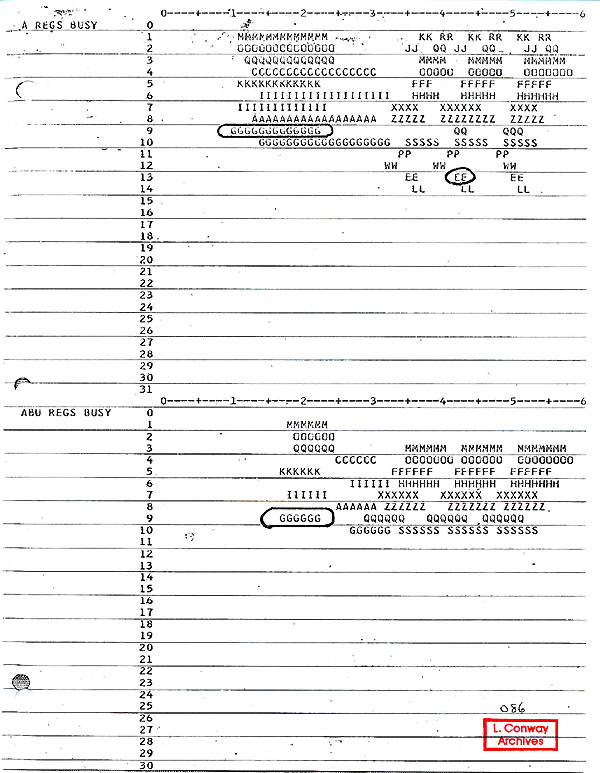

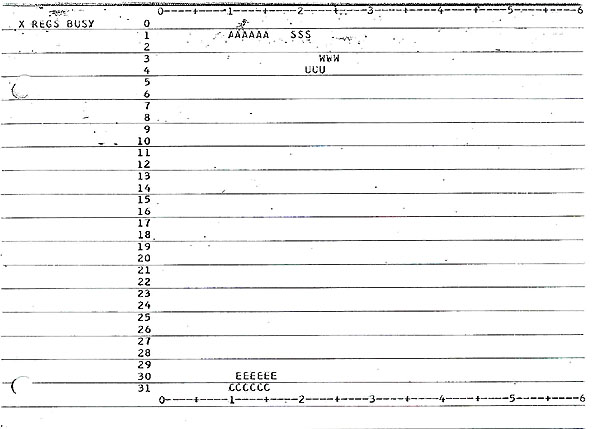

- A REGS BUSY: When an OP is issued from the A contender stack

to a functional unit, the A destination register of the OP is

marked busy with the OP marker. This is used to interlock the

issuance of other OPS in the contender stack (which use that

destination register) until the result arrives at the register

( or is available for bypassing to the input of another facility).

-

-

- 2-10

IBM CONFIDENTIAL

-

-

- ABU REGS BUSY: The A Back-Up Registers are the destination

registers for A loads and X to A moves (instructions issued from

the X unit contender stack). At the time of issuance the op marker

is placed in the ABU REGS BUSY position corresponding to the

op destination and remains till the load or move is completed.

-

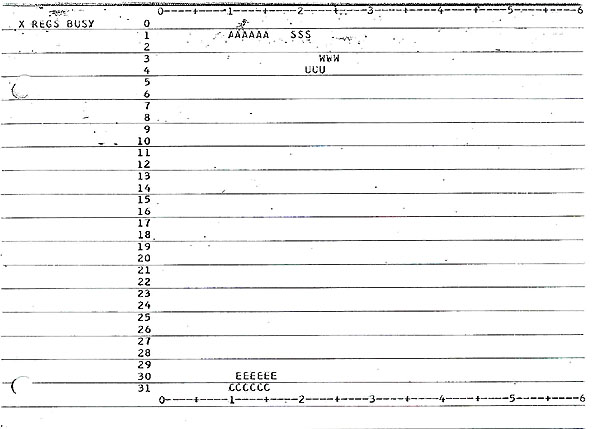

- X REGS BUSY: The busy bits for the X Registers, similar to

the A REGS BUSY described above.

-

-

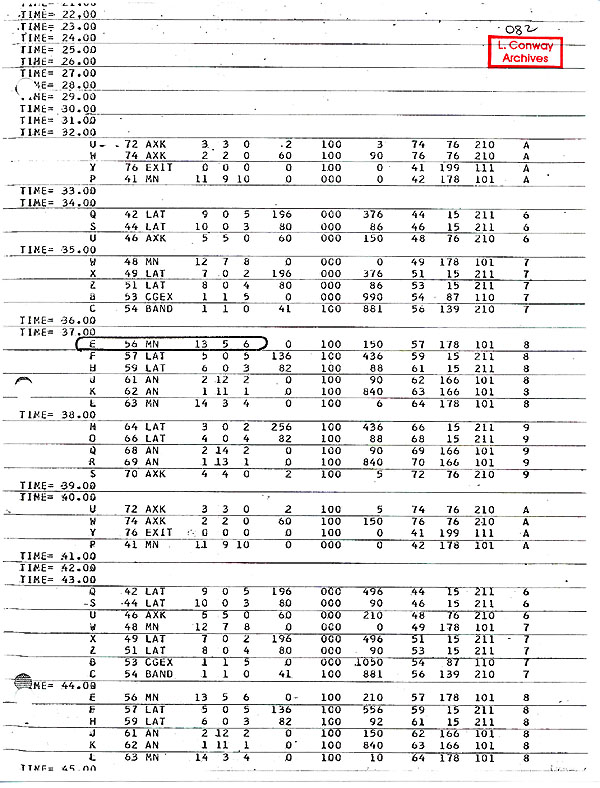

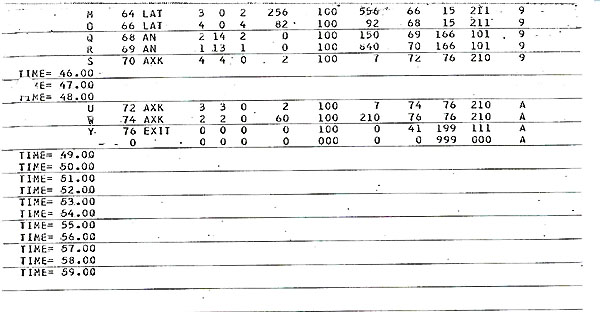

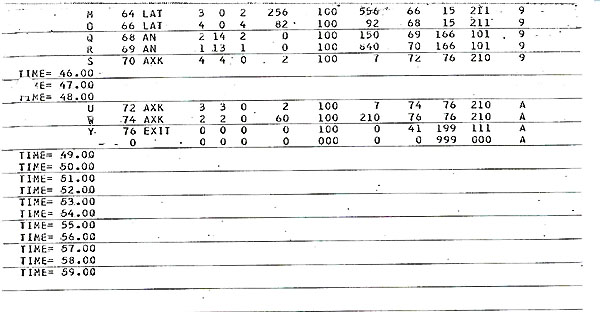

- Example of Timing Simulator Output

-

- At the end of this section is a copy of the output listing

for a typical run of the Timing Simulator. The parameter page

is followed by 3 pages listing the input trace for the first

100 cycle period of time. Then 4 pages are listed containing

the timing charts for the first 100 cycles.

-

- The program being timed is a version of Crout Reduction.

In this case the MPM is active for only 58 simulated machine

cycles--a starting transient is followed by three passes through

the inner loop of the program.

-

- The interpretation of the timing charts can be somewhat complex.

In this memo only a few simple illustrative examples are given

which follow the paths of certain instructions of the sample

program through the various sections of the machine.

-

- A thorough knowledge of the MPM hardware controls and considerable

practice are necessary for a complete interpretation of the timing

charts. However, certain subsets of the charts maybe studied

with a detailed knowledge of only that section of the MPM. For

example, someone interested in compiler scheduling of instructions

could focus his attention on the performance of his input programs

in the A and X BUFFERS and A and X FACILITIES, observing the

effects of various schedulings on the timing through these units.

A knowledge of the interlocking rules of the contender stacks

and of the busing and facility structure would be sufficient

to get a start at this.

-

- Certain simple observations may yield useful measures of

MPM performance on the input program. The overall time of the

run is easily determined. It is given as the upper time limit

on the last set of pages listing timing charts for the run. In

our example this overall run time is 58 cycles. Another measure

which is often useful is the time taken to execute a program

loop. If the input program is of the type

-

-

- 2-11

IBM CONFIDENTIAL

-

-

- which repetitively executes a loop, the loop pattern will

be obvious in the A and X FACILITY busy markers on the timing

charts. This is because a given op has the same marker symbol

each time the loop is executed (the marker is determined by the

instruction address). Thus the loop time is found by measuring

from marker to similar marker in the A FACILITIES for example.

In our sample output we find that the MPM executes the program

loop 3 times in the, FLOATING MULTIPLIER between cycle 33 and

cycle 52. The pattern has not yet settled down to a repetitive

one in the example, but the loop time is seen to be approximately

8 cycles.

-

- Some detailed examples follow. Refer to the sample listings

at the end of this section.

-

- Instruction Fetching: At time = 1 an instruction fetch

request to fill IB(1) has been placed on the MEMORY QUEUE (1).

It is issued to MEMORY in the next cycle and (after some busing

time) we observe at time = 4 that MEMORY BOMS 1, 2, 3, 4 are

busy servicing this request. The fetched instruction is then

bused to IB(1) (not indicated in output). At time = 8 we observe

that DSPX1 and DSPA1 have been loaded from IB(1). The instructions

which were fetched are seen to be A, C, E, G, which are X OPS

and in DSPX1, and G which is an A OP and in DSPA1.

-

- Notice that instruction fetching occurs up to time = 33.

After this time the loop has been contained in the IB's and no

further instruction fetching is required to run the problem.

-

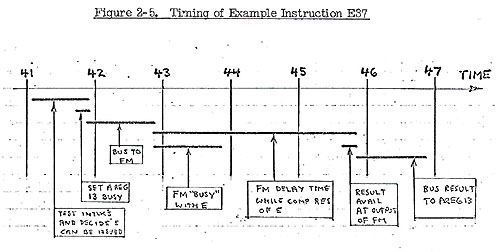

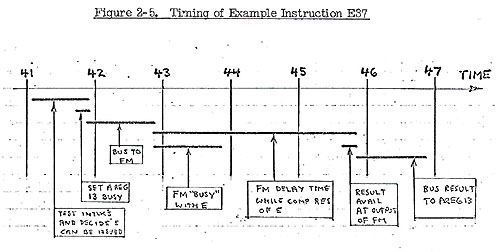

- Multiply Instruction E37: At time = 37 we find the

instruction MN 13, 5, 6, which is marked by an "E",

in the instruction trace section of the output.

-

- Let us follow the activity of this instruction through the

MPM. We observe from the trace that E was fetched into IB(8).

At time = 38 we notice that IB(8) >DSPA2 and we find E in

DSPA2(1). At time = 38 only two positions are free in the A BUFFER

so the OPS X and Y in DSPA1 move to the A BUFFER at time = 39

but E remains in the dispatchers, moving up to DSPA1(l).

-

- At time = 39, the A BUFFER has two free positions so at time

= 40 instruction E along with F are bused to the A BUFFER. We

find E in A BUFFER (4) at a time = 40.

-

-

- 2-12

IBM CONFIDENTIAL

-

-

- Now at time = 40 another multiply instruction, P, is present

in the A BUFFER and ahead of E. This multiply, interlocking E,

is issued the next cycle while E remains present at time = 41

in A BUFFER (3). At this time there are no ops ahead of it in

the buffer which interlock it so it is issued for execution and

is not present in A BUFFER at time 42. Notice that A REG BUSY

(13) goes on with the marker E at time = 42 to interlock any

OPS following E which -use A REG (13) as a source or destination.

-

- The multiplier FM under A FACILITIES is found busy with E

at cycle time = 43 (one cycle of busing required from A BUFFER

to A FACILITIES). Then at time = 44 the A REG BUSY (13) is no

longer marked by E indicating that the result of E will be available

(for bypassing) at the output of the multiplier at cycle time

= 46. Note that the delay time of the FM is 3 cycles, the multiply

E taking cycles 43, 44, 45, with the result actually back at

register 13 at cycle 47. But the multiplier is only "busy"

with E for one cycle (the REP TIME of FM) so the multiplier could

handle a new op every cycle. The timing of the busing and multiplication

are illustrated in Fig. 2-5, for the specific example instruction

E37.

-

-

-

-

- 2-13

IBM CONFIDENTIAL

-

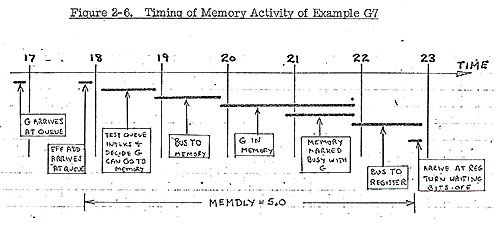

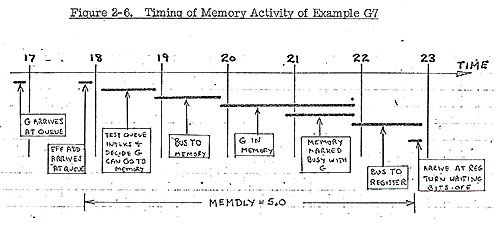

- Arithmetic Load Instruction G7: At time = 7 we find

the instruction LAT 9, 0, 31, 136 which is marked by a "G",

in the instruction trace section of the output. We observe from

the trace that G was fetched into IB(1). It is both an AOP and

an XOP and will be dispatched to both units.

-

- At time = 8, we observe from the timing charts that IB(1)

> DSPX1, IBM > DSPA1. At that time G is present in DSPX1(7),

DSPX1(8), and in DSPA1(7), DSPA1(8). G is a long OP and takes

two of the 24-bit positions in the dispatchers.

-

- Let us follow the A unit activity of G first. We note that

at time = 8 G is the first AOP to enter the dispatchers and thus

it is bused to the A BUFFER the next cycle. At time = 9 we find

G in A BUFFER (1). This part of G is a "replace" operation

and is issued the next cycle, causing A REG BUSY (9) (the destination

of the load) to be marked busy with a G at time = 10. This sets

the "front" register busy waiting for the "back-up"

register to be loaded by the X-unit.

-

- Now let us follow the X unit activity of G. Since three other

X OPS precede G in DSPX1 at time = 8, and at most 3 ops may be

dispatched to the X BUFFER per cycle, G remains in DSPX1 at time

= 9. At time = 10 it is bused to X BUFFER (2), for it is the

next op to be dispatched to the X BUFFER and both A and C leave

the X BUFFER at time = 10 allowing G to enter.

-

- We now find that G remains in the X BUFFER through time =

16. This is because it uses X REG (31) as an index and X REG

(31) is busy through time = 15 waiting for a load to arrive.

-

- At time = 16 G finally satisfies the contender stack interlocks

and at time = 17 its execution is initiated by (i) starting effective

address computation in X FACILITY EA1, (ii) placing an entry

in the MEMORY QUEUE (D), (iii) marking the ABU REG BUSY (9) with

G. The queue entry waits on the queue another cycle for the effective

address to arrive, and then is issued to memory. We note that

at time = 21, MEMORY (1) is marked busy with G, and at time =

23 the busy. bits on ABU (9) and A(9) are turned off indicating

that the load has arrived at ABU (9) and then moved immediately

to the waiting A(9).

-

- The detailed timing of this memory activity is illustrated

in Fig. 2-6.

-

- 2-14

-

-

- 2-15 (MPM timing simulator

input for CR-FS):

-

- 2-16

-

- 2-17

-

- 2-18

-

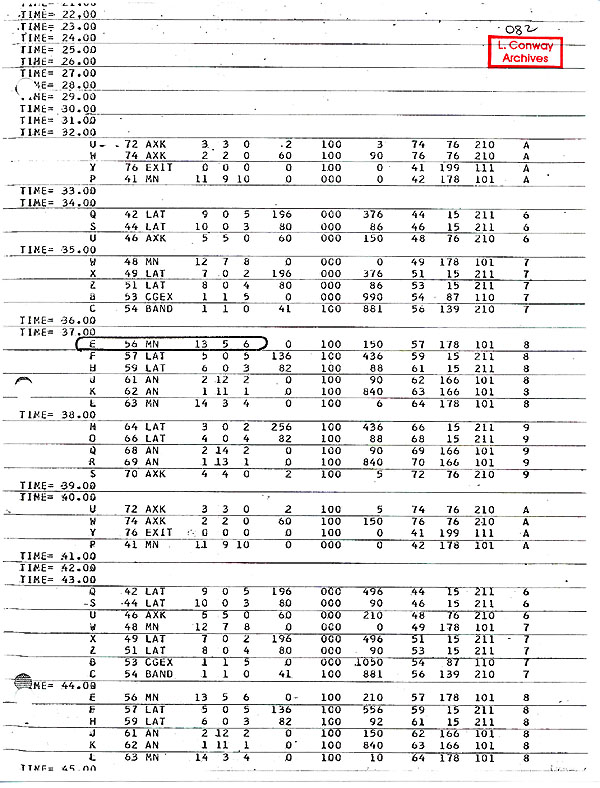

- 2-19 (MPM timing simulator output for input CR-FS):

-

- 2-20

-

- 2-21

-

- 2-22

-

-

- 3-1

IBM CONFIDENTIAL

-

-

- CURRENT JOB RUNNING PROCEDURES

-

- This section describes the procedures to be followed in order

to use the timing simulation program. These procedures are to

be completely revised and expanded in the near future so that

the programs may be stored on disk at the MOD 75 comp lab and

users may submit runs directly at the comp lab (see Section 5).

-

- To use the timing simulator at the present time:

-

- (i) Write the assembly code input program for the Unroller

(Section 1).

- (ii) Prepare the machine parameter card required for the

Timer input deck (Section 2).

- (iii) Submit these items to L. Conway, Room 203, Extension

252.

-

-

- 4-1

IBM CONFIDENTIAL

-

-

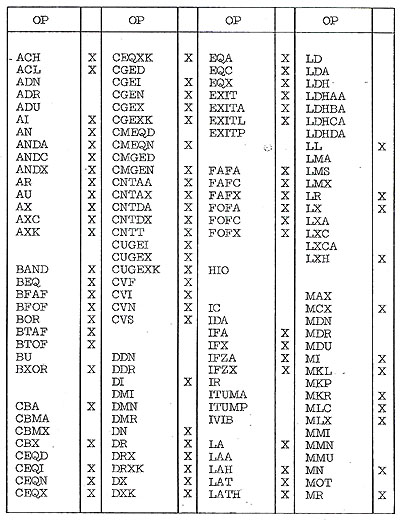

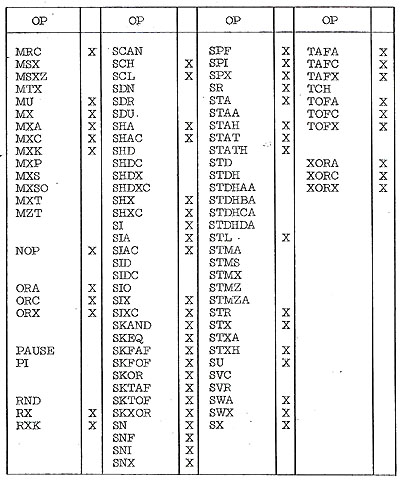

- TABLE OF IMPLEMENTED INSTRUCTIONS

-

- The table on the following pages lists the ACS-1 instruction

set op codes and indicates (with an X) if a given op is implemented

in the Timing Simulator.

-

-

- 4-2

-

-

- 4-3

-

-

- 5-1

IBM CONFIDENTIAL

-

-

- PLANNED MODIFICATIONS

-

- Certain modifications to the simulation programs are now

being made or are planned for the near future. These are briefly

described below to assist users in their planning. Updates to

this memo will. be issued as these changes are included in the

programs.

-

- Unroller Changes

-

- The control specification facilities will be extended.

-

-

- Timing Simulator Changes

-

- (ii) Additional OPS will be implemented.

(ii) New output features and options will be added.

-

-

- Job Running Procedure Changes

-

- Currently jobs must be submitted to L. Conway who will handle

the processing of the jobs. Two separate programs must be run

consecutively to process one timing simulation. This results

in a rather long overall turn-around time. To improve on this,

the two programs will be merged, with the trace temporarily stored

in core or on disk and automatically passed between them.

-

- Also, the program will be placed on disk at the MOD 75 comp

lab. The running of jobs will then be handled directly by the

user, who will submit the assembly code input deck, parameter

card, and appropriate JCL cards to call for the timing simulator.

-

- These changes will greatly reduce overall turn-around time

and allow a much greater number of users to be served than is

now possible.

-

-

lynnconway.com >

ACS Archive front-matter > IBM-ACS

MPM Timing Simulator