- Notes to readers:

This paper described an overall computer design

process based on multi-level simulation. The methods described

are of historical interest because they build on the ACS-1's

architectural and logic-level simulation capabilities to create

comprehensive design for a design process enabling error-checking

at each level of design and insurance of design consistency at

the various levels.

-

- This design process would likely have

been implemented at IBM had the ACS-1 gone into production. A

version of this paper was presented for Lynn (by others) at a

major internal IBM simulation conference in 1969 (after Lynn

had left IBM), and was well received and widely commented upon

at that conference. It is likely that this work had impact upon

later trends in computer CAD. This work also helped inspire Lynn's

later multi-level design methodology work in VLSI microelectronics.

-

- This page was created by scanning and

OCR'ing the original IBM-ACS internal paper. Page numbers correspond

to the original. See the following link for

a scanned PDF of the original paper.

(PDF)

-

- This paper has been officially declassified

by IBM, and Lynn Conway has been granted a

worldwide license

to distribute it for historical and academic purposes.

For more background

and context on this paper, refer to Lynn

Conway's ACS-Archive Front-Matter.

-

-

- August 6, 1968

Advanced Computing Systems

- Menlo Park, California

-

-

- Subject: The Computer Design Process: A Proposed Plan for

ACS

-

-

- References:

- 1. ACS AP #66-022, ACS Simulation Technique, D. P.

Rozenberg, L. Conway, R. H. Riekert, March 15, 1966.

- 2. ACS AP #67-115, MPM Timing Simulation, L. Conway,

August 25, 1967.

- 3.A Proposed Logic Simulation System, L. Conway, October

31, 1967.

- 4. System Simulation Program in ACS Engineering, P.

Shivdasani, April 24, 1968.

- 5.Proposal for a Design Procedure for the ACS System,

Uno R. Kodres, July 19, 1968 (memorandum to D. P. Rozenberg).

- 6.Preliminary Description of Traceback and Simulation

in ACS Fault Isolation, D. G. Keehn, August, 1968.

-

-

- Memorandum to: File

-

-

- [signature]

-

- L. Conway

LC:aw

-

CONTENTS

-

- 1-1 Introduction

2-1 The Overall Design Process

3-1 System Architecture

4-1 Logic Design and Engineering

5-1 Design and Process Automation

6-1 Maintenance

7-1 Conclusions

-

- 1-1

-

- INTRODUCTION

-

-

- For many years, computer designers have proposed the use

of various levels of simulation for design specification, verification

and evaluation. Simulation and automation have been applied to

some phases of the design process in a number of past projects.

-

- At the present time, in ACS, we feel that we have sufficient

practical experience in system simulation and design automation

to propose a workable system plan for the whole computer design

process.

-

- This plan has as its key element the specification of the

system level design in a high-level simulator. All following

phases of design are viewed as implementations of this system

specification.

-

- Details of this plan are presented including initial design

studies using timing simulation, design specification in a high-level

simulator, logic design verification by comparing two levels

of simulation, design automation and finally, hardware checkout

and maintenance.

-

- Design automation eliminates routine human effort in the

later design phases. Simulation allows creative human effort

where it is important -- in the initial system level planning

and evaluation. Rather than being merely a sideline in the design

process, simulation can be and should be viewed as the natural

medium of expression of the computer designer. A designer who

can quickly generate working models of his ideas can get the

feedback necessary for real design improvements. Adequate programming

tools are now available to the designer for this purpose.

-

- This memorandum presents a brief description of all the phases

and components of the design process as it might exist in ACS.

Much of this material is well established practice, and thus

the memorandum could serve as an introductory tutorial document

on this subject.

-

- The purpose of this memorandum is to make certain specific

suggestions concerning important aspects of the planning, implementation,

and operation of the total design process. The most important

of these suggestions are

-

- 1-2

-

- (i) The careful planning of the design process itself is

as necessary for success of the project as is the careful planning

of the computer design. The design process should be planned

as one integrated system. If the separate phases are planned

by different groups of people, the result will be an ineffective

overall plan with serious difficulties at the interfaces of the

phases.

-

- (ii) The plans produced should be carefully documented and

maintained and made available to all designers. A common terminology

would then develop for all the many design phases, simulation

and design auto-mation programs, design languages, etc., and

better understanding and communication would develop across design

group boundaries.

-

- (iii) It is strongly urged that the output of the Architecture

department be a formal, high-level description of the computer

in the form of a running simulator of

the system architecture. This simulator would have to be maintained

and modified as the design proceeded into later phases. This

simulator would, in effect, be the design of the machine with

all later phases viewed as implementations of the design. The,

use of a high-level language for this description is emphasized

to insure that the system description be readable and

intelligible to all designers. With the design formalized at

a high level the prediction of performance,

modification, debugging and general understanding of the design

would be greatly simplified and improved. Many of the essential

functions in the total design process proposed in this memorandum

are completely dependent upon the existence of this high-level

system architecture

- simulator.

-

- (iv) The design should be carefully "partitioned"

at the earliest possible point in the design process (i. e.,

in Architecture) into functional segments that will be manageable

by later design groups. Although it may be possible for a small

group of people to design and comprehend the entire computer

at the architectural level, it is not possible at later levels

of design. The computer must be divided or partitioned among

a number of groups of logic designers. If this partitioning is

done in architecture along functional lines, the interfaces between

partitions can be kept narrow and simple. These interfaces must

be formally specified

-

- 1-3

-

- in the high-level simulator and maintained throughout later

phases of design. The design process described in this memorandum,

including the above suggestions and the many programs implementing

the process, is not just a speculation as to what might be a

good way to do things in the distant future. There is considerable

practical experience within ACS with the various components of

the process.

-

-

- 2-1

-

- THE OVERALL DESIGN PROCESS

-

-

- Let us now identify and define the fundamental stages of

the overall design process. Then in the following sections of

the memorandum each stage will be described in some detail.

-

- The design and production of the computer passes through

four rather distinct stages. The stages are identified by their

final production of a "formal description" of the computer

in a particular "language". The output of one stage

is the input to the succeeding stage. Each stage of the process

may bethought of as implementing or redescribing the design of

the prior stage in a lower level language.

-

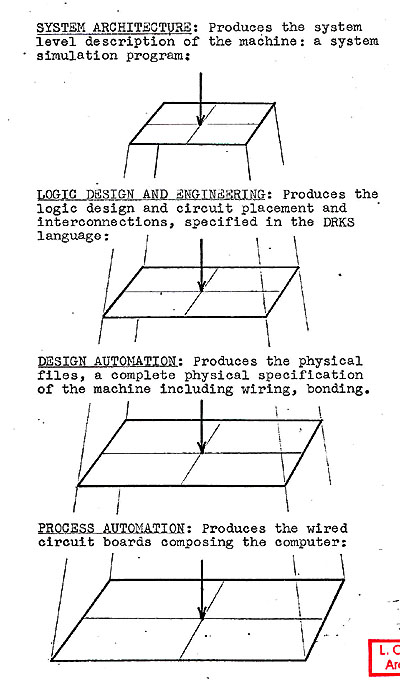

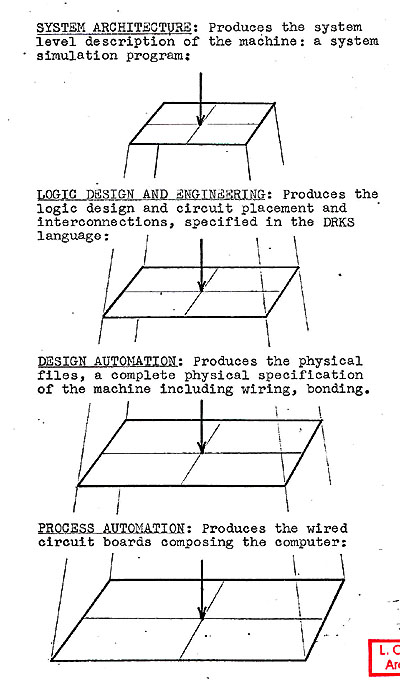

- These stages are as follows (see Figure 1 for a visualization

of the process):

-

- System Architecture: This is the planning of the structure

and function of the computer system, developed from a consideration

of predicted market conditions and technology. The plan is developed

to the level of detail of system description such that the complete

function of the system is specified. The formal description produced

by the architecture group would be a running system level simulation

program written in a high-level language. The design would be

carefully partitioned along functional lines into formally specified

partitions with fairly narrow interfaces between them. The architectural

design would consist of (i) variables and arrays in the high-level

language symbolizing the various registers and control latches

of the machine, and (ii) algorithms in the language expressing

the functioning of the control latches and the flow of data between

registers and functional units on a cycle to cycle basis.

-

- Logic Design and Engineering: The logic designers

and engineers implement the structure and function of the architectural

design in the logic circuitry and physical package of the chosen

technology. The logic designer identifies and implements all

the latches specified in the architectural design and designs

combinational logic circuitry to connect the latches and implement

the algorithms of the architectural design. This logic design

must then be mapped onto real physical circuitry. This involves

the selection of a circuit chip on which a given logic circuit

is to be found, and the placement of that chip on a particular

MCM on a board. The interconnections between all such chips,

MCM's and boards must be specified. The output of

-

- 2-1a

-

- FIGURE 1: VISUALIZING THE STAGES OF THE COMPUTER DESIGN

PROCESS:

-

- Each stage produces a partitioned description of the machine

design in a formal language, Each stage implements the design

of the preceding stage. in a lower level language, with the design

then containing more detail but performing the same function.

The partitions can pass thru the process independantly.

-

-

-

- 2-2

-

- this design phase is a formal specification of the logic

design, placement, and interconnections in the input language

to the Design Record Keeping System (DRKS), which stores the

design in a set of computer files. An alternative logic description

language is now in development.

-

- Design Automation: In the design automation phase

a set of computer programs operate upon the design filed in DRKS

to produce as output a complete physical description of the computer.

This is done on a board by board basis. Note that in the DRKS

system the various pads which must be interconnected to form

a net are specified. However the actual route of wiring to connect

these points is not. This wiring of all the nets on a board is

computed by a wiring program. The pattern for bonding the wires

to the pads is completed, and terminating resistors are assigned.

The result of this design automation phase is a set of computer

files which contain the complete physical description of all

the boards of which the computer is composed.

-

- Process Automation: We now have a complete physical

description of all the boards. But how do we actually wire a

board; what sequence of wire placements should we make? We must

compute an orderly and feasible sequence of wire placements to

be made by wiring machinery. The process automation programs

operate on the physical files to produce a set of tapes which

drive the wiring machinery through the proper sequence of operations

to wire the boards of the computer. The output of this phase

is the physical computer itself.

-

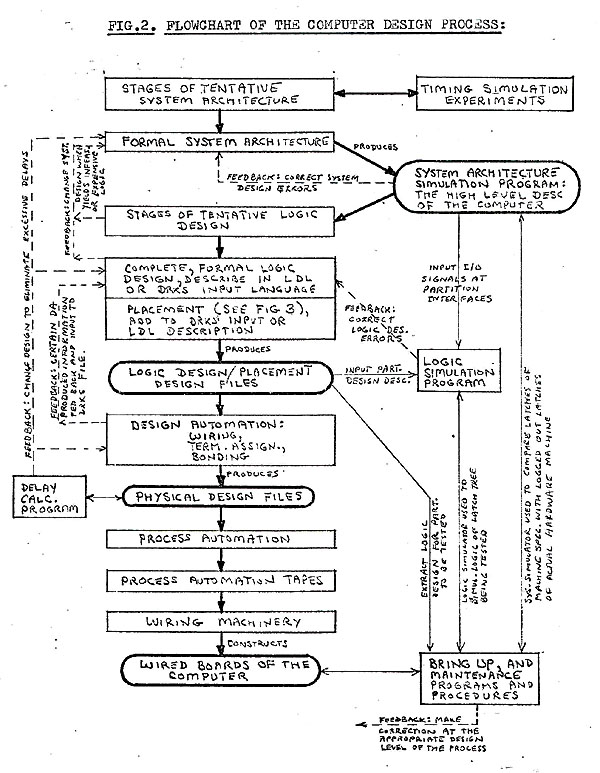

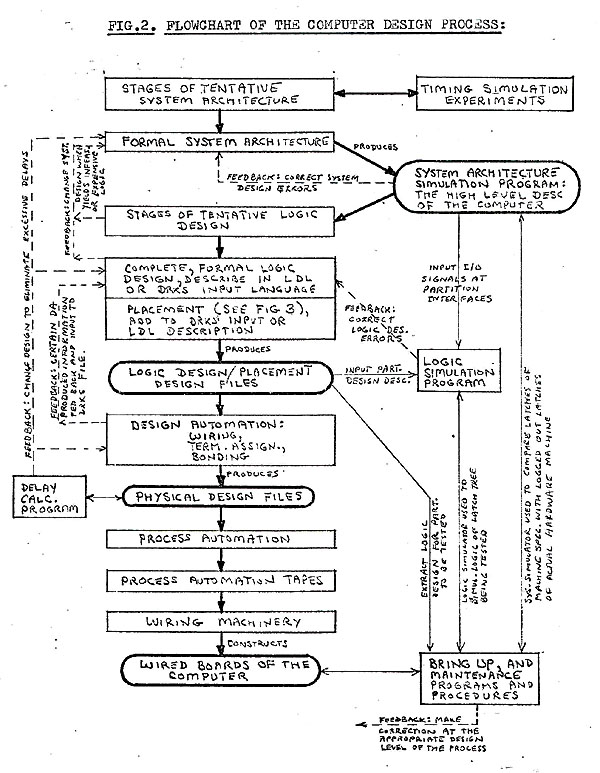

- We are now ready to study the design process in more detail.

Figure 2 is a flow chart of the stages of the design process

which indicates the various computer programs used at each stage

and the interaction of the various stages. This flow chart serves

as a basis for the detailed descriptions of each stage which

follow in the later sections of this memorandum.

-

- 2-2b

-

-

-

- 3-1

-

- SYSTEM ARCHITECTURE

-

-

- The function of the system architecture phase of design is

to produce a system-level specification of the machine. In the

design process as described in this memorandum this specification

is to be in the form of a running system simulation program.

-

- Tentative System Design: The development of a system

design which effectively meets cost and performance requirements

calls for considerable experimentation with tentative system

designs. The design will thus pass through these tentative, experimental

phases until the experiments

indicate that it is satisfactory. Then the design can be completely

placed into a formal description.

-

- Now, how can one experiment with a tentative computer design?

It turns out that this is well established in ACS --by using

a timing simulation program. See Reference 2 for a description

of a past timing simulation effort, and Reference 1 for the simulation

technique used in that effort.

-

- The timing simulator is written at essentially the same level

of description as the later system-level simulator and using

the same simulation technique. However, it can be simpler and

quicker to write because it does not require a data flow. Only

the timing of control operations is relevant to timing simulation.

The input to the timing simulator is the stream of instructions

to be processed by

the simulated computer, and the output of the simulator is a

chart of the activities in the various machine registers, initiated

by the instructions being processed, as a function of time. The

detailed model of the proposed control structure can thus be

tested quite accurately to predict performance and uncover design

bottlenecks.

-

- In order for timing simulation to really interact with and

affect the system design, the simulator must be running while

the system design is in development. This is only possible if

-

- (i) The system architects really want a simulator, believe

in its value, and help in its production.

-

- (ii) The timing simulator is written in a high-level language.

This will make algorithm production and documentation much easier

than would assembly coding. Also, the timing simulator would

be consistent with and a basis for the later system simulator.

3-2

-

- (iii) The architects participate in its writing.

-

- If the simulator writer(s) must form all the detailed algorithms

specifying a tentative design, then the simulator will lag the

design by many months, perhaps 4 to 6 months. However if the

architects specify their tentative design in detail, then the

coding of these designs would be a far simpler process and might

lag specification by only one or two months.

-

- This simulator should be partitioned along the same lines

as the machine and interfaces identified early in the design

processes. Then the separate partitions could be designed independently

with unspecified partitions modeled in the simulator by dummy

subroutines which roughly approximate the function of those partitions.

In this way the entire machine can be simulated as early as possible

even though some sections are not completely designed. Studies

can then be made on those sections which have been designed.

-

- Formal System Design: When timing simulation experiments

indicate that the system design is satisfactory and unlikely

to change greatly, the construction of a complete system simulator

describing that design can begin.

-

- The design will already have been partitioned. Engineers

from the logic design groups assigned to implement these partitions

could work along with the architects to write the system simulator.

This simulator must be carried uniformly to the latch level of

detail in order to be useful in later stages of design. The engineers

could see that this requirement is met and that all algorithms

specified for latch to latch operations in one cycle could probably

be implemented in combinatorial logic without breaking the machine

cycle.

-

- There is experience in ACS with this sort of simulation,

where a number of engineers write the program rather than having

a simulation programmer do it. See Reference 4.

-

- Note that this production of the system level design by both

architects and engineers blurs the traditional boundary between

the two functions. Both groups of designers work on the system

level design, but from different orientations.

-

- When the system description is complete, it can be run as

a simulator and the design debugged at this level by running

many actual programs on the "computer". As the later

stages of design are completed,

-

3-3

-

- much information will be fed back to the architectural stage

and force revisions in the system description. For example, many

algorithms will not turn out to be realizable in logic in one

cycle, and will have to be respecified, changing the system description.

This system description must be accurately maintained if the

design process as described in this memo is to function properly.

-

- The availability of an accurate, maintained system level

simulator will result in:

-

- (i)Accurate performance prediction- -potential users, compiler

writers, etc., can run code on this simulator and predict machine

performance and optimize their programs.

-

- (ii) The logic design of the machine will proceed directly

from the high-level description and thus will progress more rapidly

and with better communication between design groups working on

different partitions.

-

- (iii) An effective logic simulation can be performed to compare

the logic design of a partition with the system specification

of that partition. The system level simulator can produce the

input/output signals on the partition interface which can then

be used to "drive" the logic simulator. More will be

said about this very important logic simulation later in this

memorandum.

-

- (iv) Accurate system simulation plus accurate logic simulation

will make possible the implementation of a very effective maintenance

plan. This will be described later in this memo. See also Reference

6.

-

- The significance and importance of the system level simulator

cannot be overemphasized. It must be produced and maintained

for the proposed scheme to work. The higher the level at which

a design is formally specified, the easier it is for everyone

involved to fully understand the design, experiment with it,

and change and debug that design.

-

- This system level simulator should really be viewed as "the

machine". All later design and automation of design and

manufacture should be viewed as implementations of the system

design.

4-1

-

- LOGIC DESIGN AND ENGINEERING

-

-

- This stage of the design process produces an implementation

of the structure and function of the architectural design in

the logic circuitry and physical package of the chosen technology.

-

- In a manner similar to the system design, the logic design

and engineering pass through two phases: (i) a tentative phase

where attempts are made at implementation, often resulting in

revisions being made in the system design, and (ii) a formal

phase where the formal description of the logic and physical

placement is produced.

-

- Tentative Logic Design: When a partition of the system

has completed tentative system design and is ready to be formalized

in the system level simulator, then the tentative logic design

of that partition may begin. The tentative logic design is the

attempt at implementation of the system partition in logic circuitry

and package. These early attempts will fail because many of the

system algorithms will not be realizable in one machine cycle

of logic. A strong interaction must exist between those persons

producing the formal system specification and the logic designers.

The tentative logic design efforts must feed back enough information

such that the formal system description will have most of the

algorithms checked for feasibility of implementation in logic

and package without breaking the machine cycle time. For this

reason it is suggested that at least one of the logic designers

who works on the tentative logic design of a partition also work

along with the architect for that partition and participate in

the formation of the system level description. In this way the

partition of the system will not only reflect architectural requirements,

but will be implementable, as described, in logic.

-

- These early, tentative logic design and placement efforts

will probably be specified nonformally. The designs at this stage

are traditionally sketched out as logic circuit diagrams on "yellow

sheets". Rough. approximations of circuit placement can

be made, and then estimates of delays and circuit counts can

be generated. These estimates will be fed back, and perhaps modify

the system design and/or the logic design.

-

- 4-1a

-

-

-

- 4-2

-

- Formal Logic Design and Placement: When tentative

logic design studies have produced sufficient feedback to finalize

the system design, then the formal logic design and placement

can begin. The formal logic design must implement in logic circuitry

the function of the system design. The behavior of a partition

of the machine, as seen at its interfaces, must be the same at

both levels of design, system and logic.

-

- There are two aspects to this implementation of the system

design: the implementation of the system function in logic circuitry

and the mapping of that circuit design onto real hardware.

-

- Currently the logic design phase is done by the designer

with no computer assistance. The mapping of the logic design

onto hardware and the placement of the different levels of hardware

may be done in part, or perhaps entirely by computer programs.

-

- The mapping or partitioning of logic circuitry onto hardware

and the placement of levels of hardware involves the following

levels: logic circuitry maps onto circuit chips, circuit chips

are placed on MCM's, and MCM's are placed on the board.

-

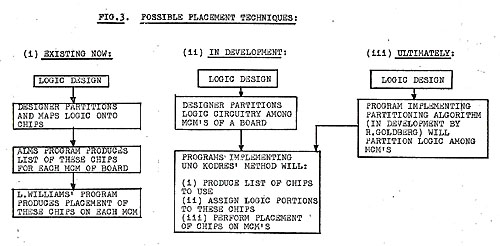

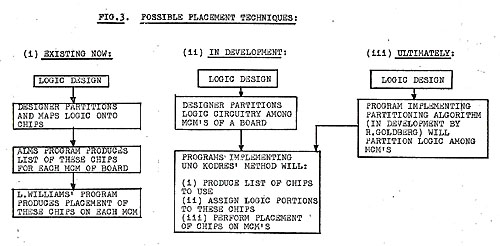

- There are a number of possible techniques that might be used

to accomplish the placement which involve varying amounts of

computer assistance to the designer. Some methods being considered

for ACS use are

-

- (i) In current use is a method where the designer must partition

the logic onto chips by hand, and then a sequence of computer

programs places the chips on MCM's on the board.

-

- (ii) In development is a placement system which will require

that the designer merely partition the logic among MCM's. The

selection of chips, assignment of logic to chips and placement

of chips on MCM's on the board would be accomplished by computer

programs. See Reference 5 which summarizes Dr. U. Kodres' work

in this area.

-

- (iii) It may eventually be possible to have the partitioning

of logic among MCM's be automated also, thus automating the entire

partitioning and placement process. Mr. R. Goldberg is working

on this partitioning algorithm. Also, Research has developed

a program, ALMS, which may be applicable.

- These three placement schemes are summarized in the flow

charts in Figure 3.

-

- 4-2a

-

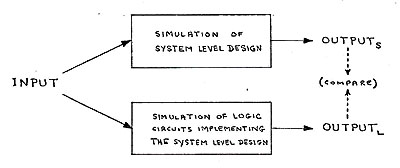

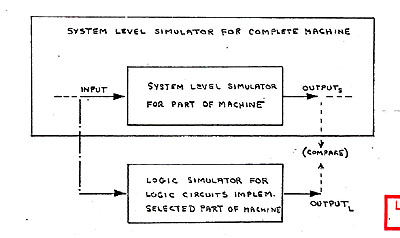

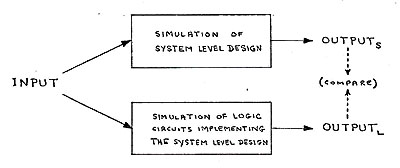

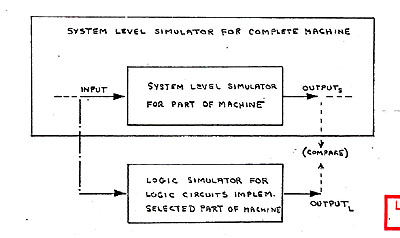

- Fig. 4. THE BASIC IDEA OF LSS: Apply the same input

to both levels of simulation and compare outputs. If outputs

are differenct then error exists in logic design:

-

-

-

- FIG.5. AUTOMATIC GENERATION FO SYSTEM LEVEL INPUT/OUTPUT,

LOGIC SIMULATOR INPUT: System level design is imbedded in

system level simulation of entire machine. When this simulator

runs, we automatically generate (and save) the I/O at the design

interface. We may later use these inputs to the logic simulator

for the same design and compare the logic outputs with the same

system level outputs:

-

-

-

- 4-3

-

- Formal Description of Logic Design/Placement: The

output of the formal logic design and placement is a formal description

of the design at this level. The language in which this description

may be placed is the DRKS input language. DRKS is the design

record keeping system which files the logic design and placement

information.

-

- An unfortunate aspect of the DRKS language is that it imposes

a totally arbitrary level of partitioning on the design description:

the ALD sheet (logic diagram sheet). The design is input to DRKS

by drawing logic diagrams on sheets of a fixed size and then

describing the drawing by statements in the DRKS language.

-

- This partitioning onto sheets is usually too fine to correspond

to any useful design partition. The designers partition of the

machine and even various functional entities within that partition

will contain logic circuitry requiring many, many ALD sheets

to describe. The language used to input DRKS is awkward to use,

and describes the sheets rather than the logic directly. The

statements of the language are usually formulated by someone

other than the designer, who merely sketches the sheets.

-

- It is strongly suggested that an alternative Logic Description

Language (LDL) be developed and used so that the designer can

more easily specify his logic design in a formal language. In

this way the processing and understanding of the logic designs

might be improved greatly. Dr. J. Cocke has proposed a tentative

version of such a language. Dr. R. Love, Mr. P. Shivdasani and

I are now working on completing the specification of this language.

-

- An important reason for the use of sheets as the formal logic

design description has been the traditional use of these sheets

by CE's who maintain the hardware. As we shall see later in this

memorandum (Section 6), the importance of the sheets may be reduced

because their use by CE's can be minimized by using improved

maintenance methods.

-

- If the ALD sheet were needed, perhaps in some central maintenance

facility, a form of ALD sheet could be generated by program from

the design files formed from LDL input. Thus there is no real

reason for requiring that the design be specified by sheets initially.

Another development which might really de-emphasize the importance

of ALD's is the possible use of prototype sheets. This plan involves

the use of a very limited total number of chip-types. Each chip

would be described by a prototype sheet. There would thus be

only a limited number of possible sheet types. These could be

stored as macros in a file. A design would be described by program

statements

-

- 4-4

-

- indicating the interconnection of such chips. No actual sheet

input would be necessary as the sheet would be implied by chip

type. Thus the logic could easily be described by a simple form

of LDL. Appropriate ALD sheets could be very easily generated

by program on those rare occasions

- when someone really needed to look at them.

-

- Logic Simulation: When the logic design of a partition

of the machine has been completed and formally described, it

is very desirable to verify that the logic design correctly implements

the architectural specification of the partition before going

any further into the design automation and process automation

phases. An error found at this stage will be much easier to correct

than if found later on.

-

- This verification of the logic design is performed using

a logic simulation program. A partition of the design can be

simulated on this program. Input signals are supplied at its

interface and the logic simulator produces the output signals

at the interface.

The major problem in this sort of logic simulation is the generation

of test cases of interface input signals and expected output

signals. The generation of a large enough set of such signals

to moderately debug a partition of logic would be a very costly

process if done manually. It would probably be possible to generate

only a rather small number of such tests.

-

- There is a solution to this problem. If the system level

simulator and logic description of a partition are really different

levels of description of the same entity, then they should behave

the same at the partition interface. Thus it would be possible

to run a program on the system level simulator and store all

the 1/0 signals on a partition's interface while the program

is running. Then these signals could be used to input and compare

against the logic of the partition when it runs on the logic

simulator. In this way many tests could be automatically generated.

The tests would be consistent over the whole machine; if we debugged

the logic of all partitions on a given program, then when we

put all partitions together later, they might all function properly

together when running that program.

-

- This idea of using two levels of simulation to debug the

logic design has been extensively studied and described in an

earlier memorandum. See Reference 3.

-

- Figures 4 and 5 graphically portray the idea of a Logic Simulation

System (LSS) using two simulators: a system simulator which provides

input/output signals for the partition which runs on a logic

simulator.

-

-

- 5-1

-

- DESIGN AND PROCESS AUTOMATION

-

-

- Suppose we now have a verified logic design along with physical

placement information resident in the DRKS files. There is still

a long way to go before the machine can actually be constructed.

The remainder of the design process is completely automated,

however.

The steps in the design automation process are as follows

(greatly simplified):

-

- (i)The records describing the logic design and placement

for a board are selected from the DRKS files.

-

- (ii)The nets on the board must now be wired. This involves

determining the best path for wiring together the points of a

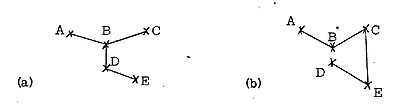

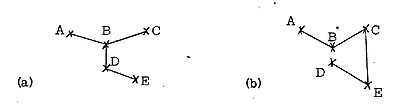

net subject to the wiring rule constraints. For example, given

that points A, B, C, D, E must be wired together we must decide

whether to wire as in (a), (b) or some other way.

-

-

-

- (iii) When the wiring has been calculated for the nets, we

must assign the location of terminating resistors for

the nets.

-

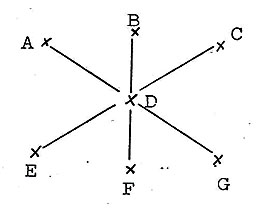

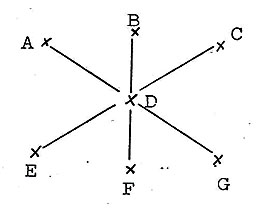

- (iv) Suppose we have wired A, B, C, D, E, F, G together as

follows:

-

-

-

- 5-2

-

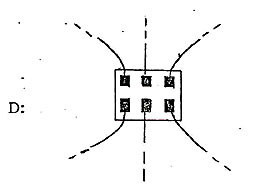

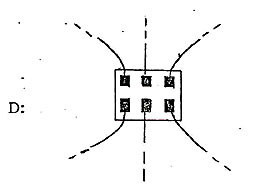

- We must now decide how to bond the wires on each pad of the

net. In the above example, D would be bonded as follows:

-

-

- The actual DA programming becomes somewhat involved because

a situation may arise in the later stages of processing which

cannot yield a solution, and this will have to be fed back to

the earlier phases and a new pass made through the DA programs.

-

-

- After the design automation is completed, we have in a "physical

file" the complete physical specification of the boards

of the machine.

-

- At this point we have sufficient information to perform delay

calculations to determine the circuit and wiring delays in various

paths through the machine. Computer programs can be written to

perform these calculations. Excessive delays will necessitate

design changes.. This raises an interesting point: We have proposed

four formal specification levels for the design. Thus, we can

envision four levels of design simulation: system, logic, "A-C"

logic including delays, and finally actual running hardware.

-

- Unfortunately, the "A-C" logic simulation, including

physical delays, is not really feasible for a machine of the

size we are designing. Even the usual logic simulation must be

partitioned, and the AC logic simulation includes much more detail.

So all we can do at this level is delay calculations on paths

through the hardware. It is of theoretical interest however to

note that with sufficient machine power a simulation at the physical

level could be performed and make this stage of the proposed

process similar to the preceding stages in the use of simulation

to verify the design.

-

-

- 5-3

-

- The phase in the design process which results in the production

of actual hardware is the process automation phase. After appropriate

reformatting, the information in the physical file describing

a board is input to the process automation programs. These programs

produce as output the tapes which drive the wiring machinery

which actually constructs the boards of the computer

.

Now, how can the boards (or MCM's) produced by the process automation

be debugged? Even if the design at the system level and logic

design level is error free, defects or errors may have been introduced

in the manufacture or wiring of the circuitry.

-

- It is possible to partially debug the hardware in an economical

manner by using the two levels of simulators to generate test

signals.

- The signals could be generated as follows: The system simulator

can produce input signals for the logic simulator while running

a particular program. This would be done for the logic simulation

of the partition of the machine which contains the hardware to

be tested (usually the hardware would be a small subset of a

partition). All of the signals internal to the partition are

generated during the logic simulation. Thus the signals at the

interface of the hardware to be tested could be extracted, and

filed, while running the logic simulator.

-

- Of course this method of debugging is only partial. Not all

possible input-output test patterns would be generated for the

hardware. However, this is a very special form of partial debugging:

the same program could be run on the system simulator to generate

tests for all hardware components. Thus, although only partially

debugged, the hardware will run that particular program when

it is all put together.

-

- The key point to note is that the partial debugging is uniform

over the whole machine. Of course many programs could be run

-- the number depending on the economics of the situation. Diagnostic

programs could be used for this hardware test generation. Then

the machine, when constructed, would run the diagnostics to isolate

residual hardware errors under normal maintenance procedures.

-

- Note that if each piece of hardware were very thoroughly,

but not completely, debugged with traditional methods, there

would be no assurance that any program would run when the pieces

were put together.

-

5-4

-

- Thus, the partial, but uniform, test generation could be

a very economical method of quickly getting hardware to the point

where it will run at least some programs when integrated into

the whole machine.

-

- This could serve as a basis for planning the bring-up of

the machine.

-

- 6-1

-

- MAINTENANCE

-

-

- The design process is not completed with the wiring and construction

of the computer. A bring-up of the computer must be accomplished

and the machine must be maintained. Bring-up may uncover design

errors at any of the stages of design. In addition to the correction

of hardware failures, maintenance will involve the installation

of engineering changes. Thus, both of these activities involve

cycling back through the design process and both are strongly

tied into the network of simulation and automation programs used

in the design process.

-

- At this time the bring-up process has not been completely

defined. However, a complete maintenance procedure has been defined

by Dr. D. G. Keehn (See Reference 6). This plan will be briefly

described here to indicate how it depends upon the simulation

programs. Some leads to ways of planning bring-up might be uncovered

in this maintenance plan. The scheme functions as follows:

-

- (a) Diagnostic programs running on the ACS computer detect

an error. The program causing the error is identified.

-

- (b) The error producing diagnostic- program is repeated on

both the ACS computer and on the system architecture simulator

running on a smaller diagnostic computer. The ACS computer's

latches are loaded out each cycle and compared to the latches

of the simulator. The failing latch and cycle of failure are

identified.

-

- (c) A traceback program is run on the diagnostic computer,

operating on the logic files, to find all latches which could

set/reset the failing latch in one cycle. This is the latch tree

of the failing latch.

-

- (d) All scopeable points in the logic of the selected latch

tree are found from the design files and output by another program

running on the diagnostic computer.

-

- (e) The logic of the latch tree is extracted from the design

files. A logic simulation of the latch tree is performed for

the cycles of interest: the cycle preceding failure and the failing

cycle. The scopeable point values are output for these cycles.

-

6-2

-

- (f) A technician can now scope the ACS machine at the appropriate

points and compare the values with the above values for the cycles

of interest. This will isolate the point of error.

-

- (g) The technician then decides what unit of hardware to

pull and replace in order to correct the failure.

-

- There are some very interesting operational characteristics

in this maintenance plan:

-

- (i) The diagnostic computer can be physically distant from

the ACS machine being repaired with communication between the

two locations handled by teleprocessing. Thus, one central diagnostic

computer and maintenance system could maintain several ACS machines

in the field.

-

- (ii) The person repairing the machine in the held need not

be a CE in the usual sense. He could be a technician instead,

for no knowledge of the functioning of computer logic would be

required to perform repair work.

-

- (iii) Because of (ii), it is clear that the distribution

of ALD sheets to many CE's in the field would not be necessary.

The significance of these sheets is thus greatly reduced.

- This particular maintenance plan has significant advantages

over previous plans. These advantages are bought at a price:

dependence on the existence of accurate system architecture and

logic simulators.

7-1

-

- CONCLUSIONS

-

-

- We have now covered all the phases of the design process

in some detail. For the sake of simplicity and brevity, the presentation

has treated these phases as separate activities which follow

each other in a serial manner.

-

- The actual design situation is obviously far more complex

and requires careful planning, scheduling and management of human

and machine resources. There are three factors in the process

(not fully developed in this initial memorandum) which lead to

this additional complexity:

-

- (i) Design phases do not follow serially, but overlap in

time. For example., the tentative logic design may be proceeding

while the formal system specification is still in process.

-

- (ii) There is a relative independence of the design of different

partitions. We might be far along in the design process on one

partition of the machine, but only experimenting at the system

level with another partition.

-

- (iii) There is consistent feedback (as indicated in Figure

2) from later phases of design to earlier phases. Very often

the design at a given phase cannot be feasibly or economically

implemented at a later stage and must be modified.

-

- Therefore this basic plan for the design process must be

made considerably more detailed and account for these additional

complexities before it is really a working plan for the process.

-

- This elaboration of the plan will have to await the feedback

produced by this memorandum.

-

- In conclusion, it is felt that the suggestions proposed in

this memorandum, especially the fundamental uses of the system

simulation program, can lead to a workable system plan for the

whole computer design process if they are properly elaborated

and detailed.

-

- A key factor in reaching this conclusion is the existence

of practical experience within ACS in the separate phases of

the plan.

-

- It is hoped that this memorandum will stimulate discussion

and new ideas on this subject. Your comments and criticisms concerning

the various suggestions made herein are welcomed by the author.

-

-

-

lynnconway.com >

ACS Archive front-matter > Design Process

-